Introduction

Composite Material

Characteristics

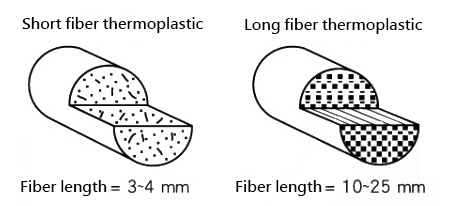

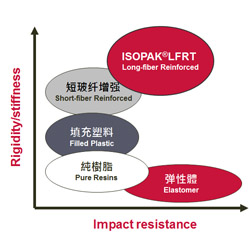

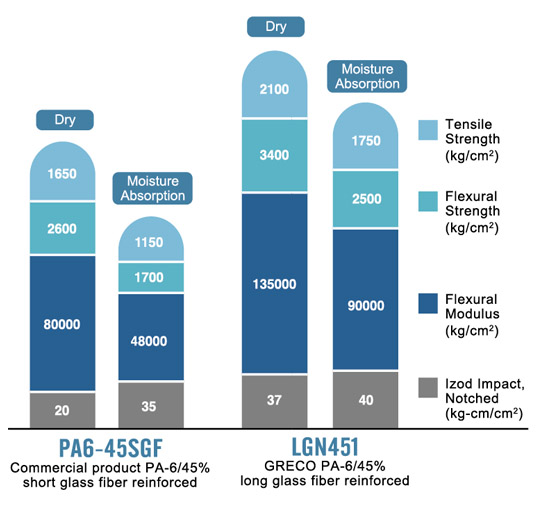

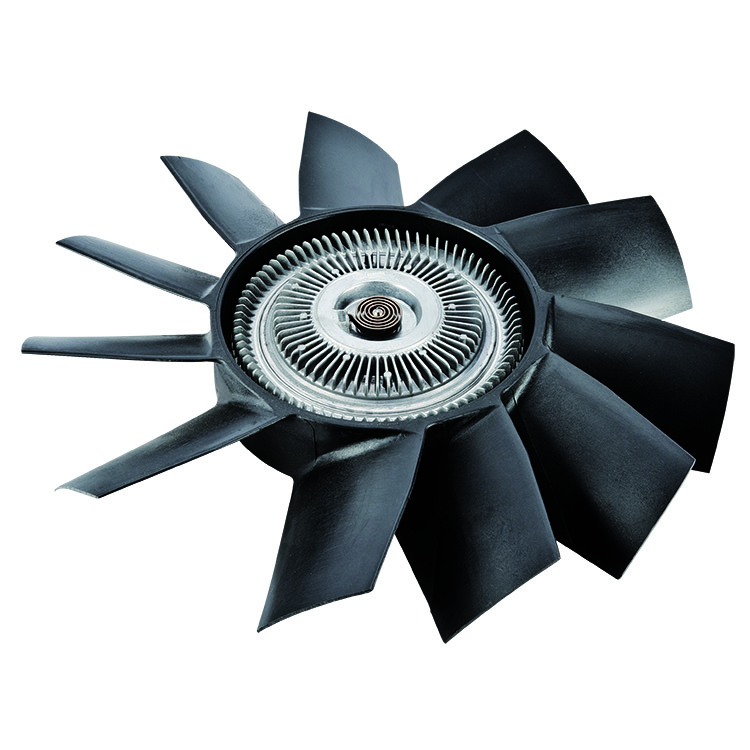

LFRT(long fiber reinforced compounding material) has excellent rigidity stiffness and impact resistance. It can be used to replace the metal material of the industrial parts and efficiently lightening the weight. The surface of the product will have nice gloss and smooth. The abrasion resistance and size’s stability are better than other compoundings.

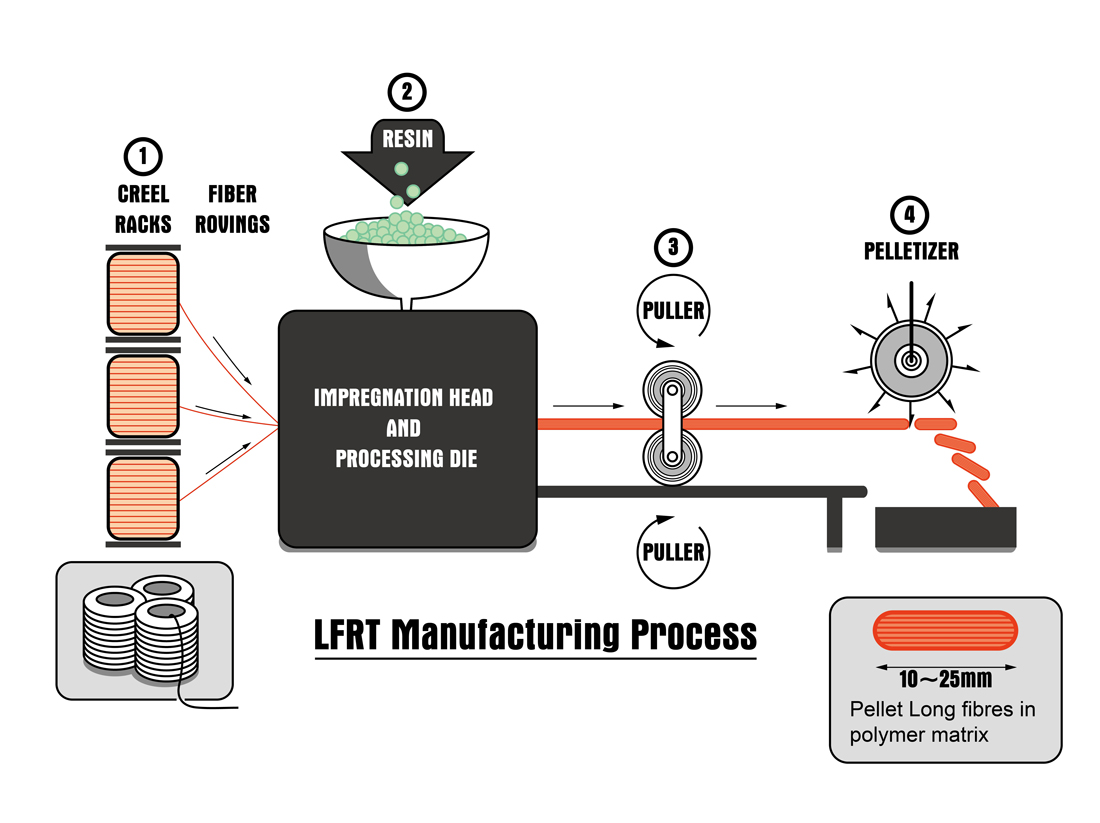

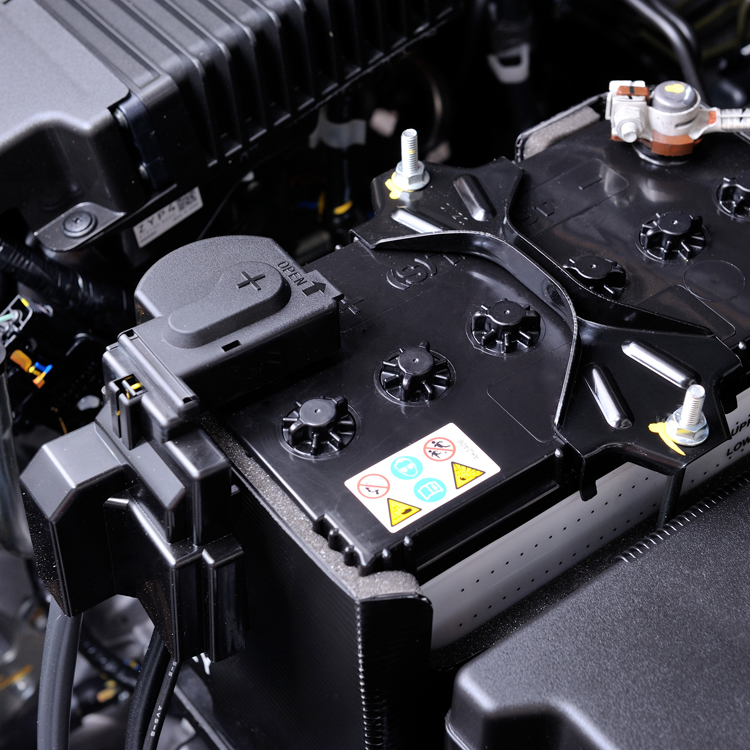

The length of LFRT pellets is 6mm to 12mm. LFRT can be applied to the case of electrical instrument, car parts, machinery parts, exercise gear, and IT industries. It also has the ability to block the EMI.

- Has Flexibility of the Thermoplastics and High Intensity of the Long-fiber.

- With the stiffness of the continuous reinforced-plastic.

- Can be Processed Rapidly by the Injection.

- Has the abilities of fiber and plastic.

For processing and application, the advantage of the LFT are as follows:

- The method of processing and molding are the same with SFT(short-reinforced fiber material). The LFT can highly and obviously increase the mechanical property of the product. This is because the long fiber can stand the long-size in the 3-Dimension of the thermoplastic resins.

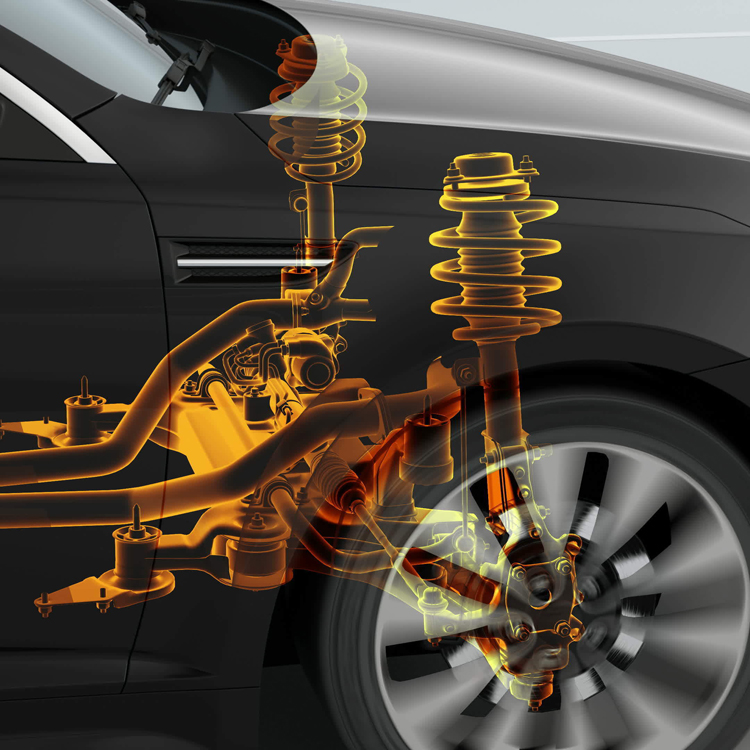

- The Specific strength of the Aluminum is 9.8%.And the Specific strength of the LFT can reach 17.2%. This is included the superior of low shrinkage, low creep, anti-fatigue and high size-stability, especially for the application of machinery, car parts, and structural component.

- The LGF has better designing-flexibility than the GMT and CFRT. It can be easily injection in the complex shape and molding. The general GMT simply can be compression molding.

- The LGF is recyclable. It can highly meet the requirement of the high performance thermoplastic compounding material.