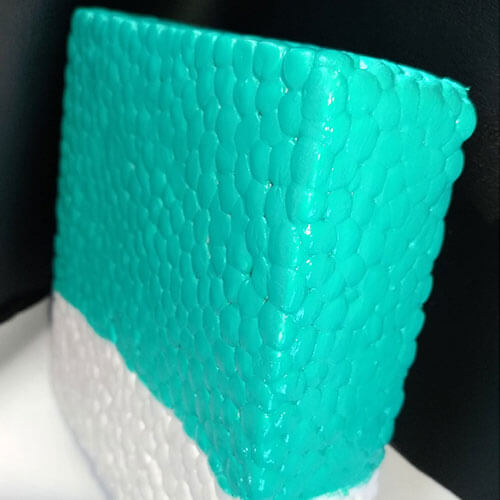

Expanded TPU

Low density + High elasticity

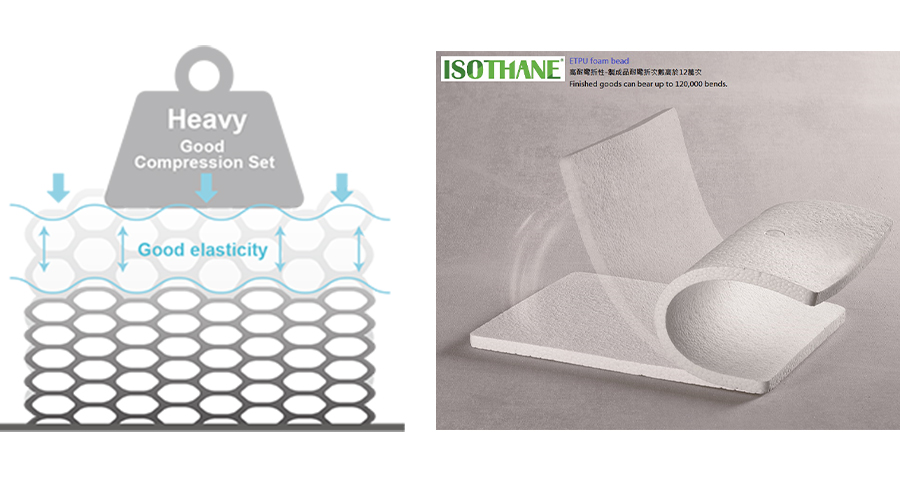

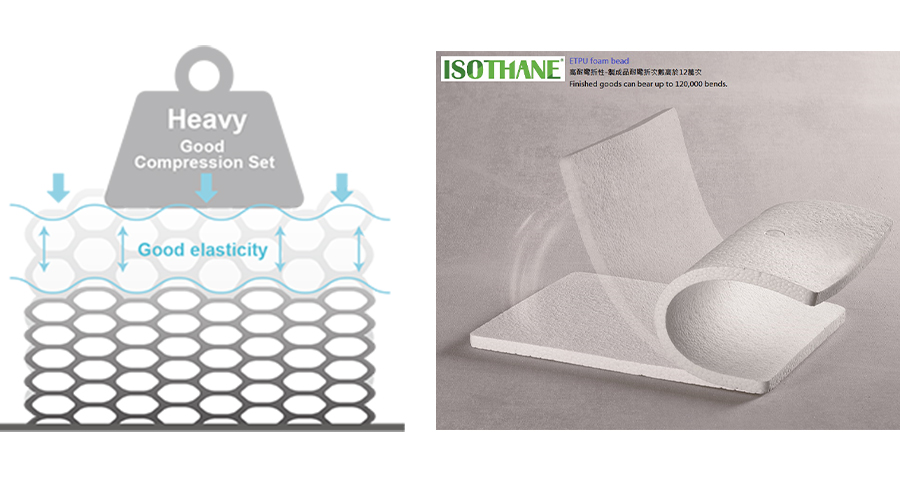

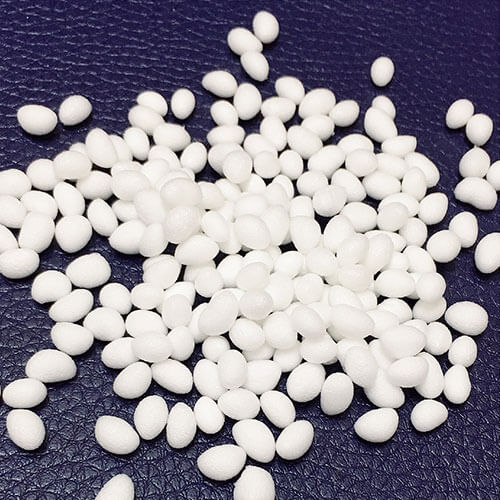

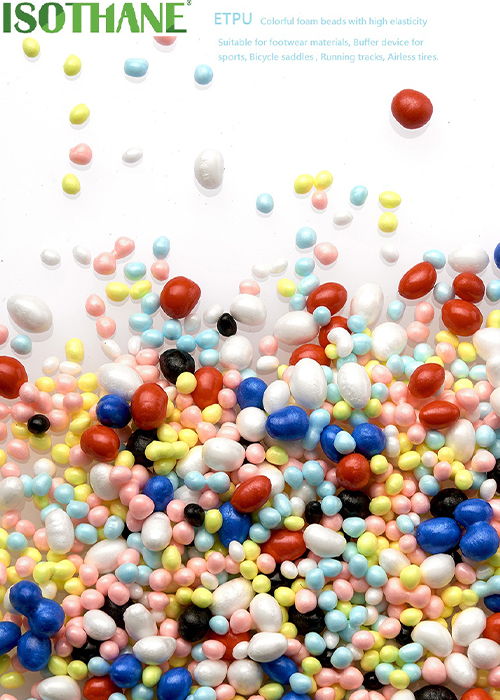

ISOTHANE ETPU has light density and high elasticity. Even at negative temperature, it can withstands prolonged and repeated compression without permanent deformation. ETPU (expanded thermoplastic polyurethane) offers a perfect combination of soft texture and great elasticity. ISOTHANE ETPU- colorful foam beads with high elasticity, customized different color and particle size for lightening era.

- Super response : Rebound rate could be up to 63%

- Low density : Density : 100-200 kg/m3

- Good performance at low temperature : High elasticity and softness even at -25°C.

- Anti-yellowing : Anti-yellowing material, also have non-yellowing grade.

- Good abrasion resistance : Very low abrasion.

- High flexing endurance : Finished goods can bear up to 120,000 bends.

- Low compression set : Compressed reply is higher than 90%.

- Eco-friendly material : All raw materials and processes are environment-friendly.

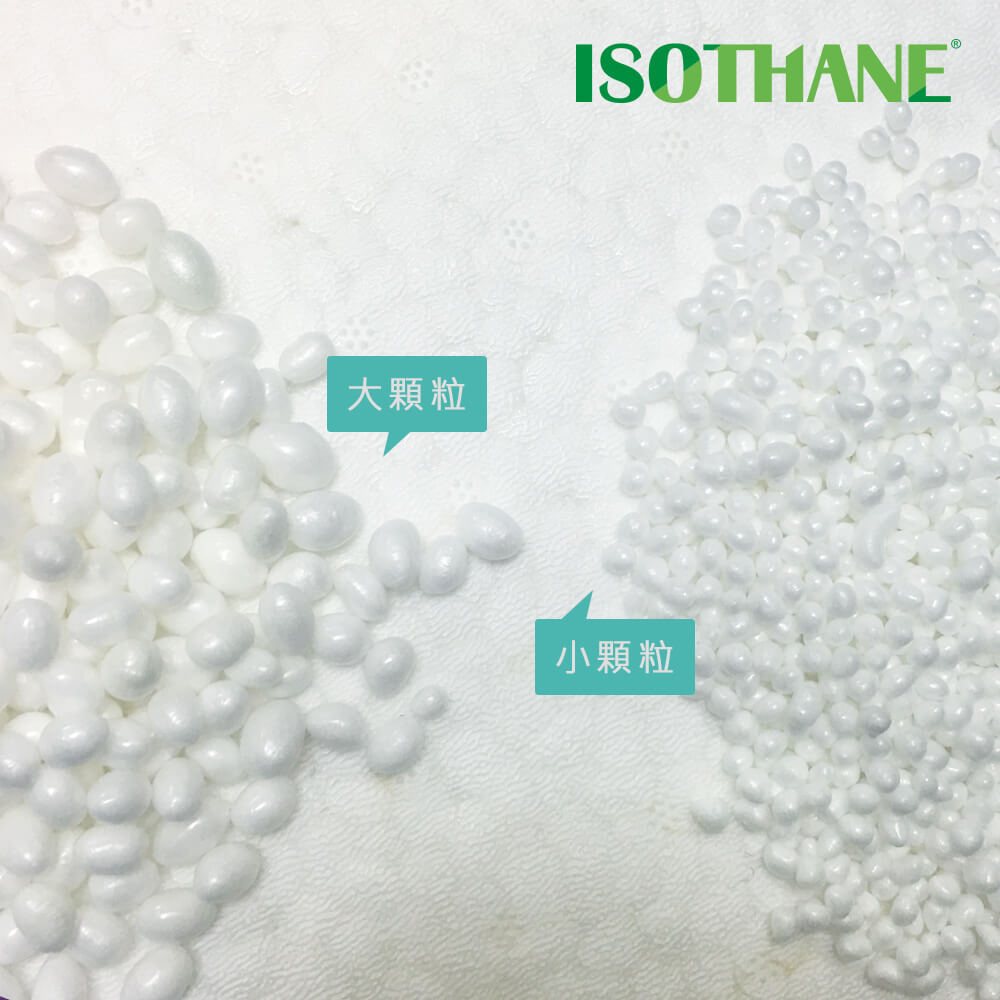

ETPU Foam Particles

- Expanded beads can be provided with different size according to the requirements.

- Molded hardness can meet different specification according to each requirement.

- Stable product quality and mass production Colors TPU foam beads available.

What is the E-TPU foam beads

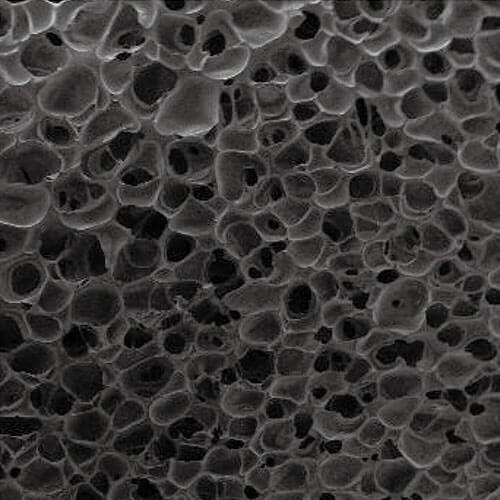

Microsocopic cross section

COMPARISON:

| Properties | TPU Foam | EPP | EPS | EPE | EVA | Foam PU |

|---|

| Density (g/cm3) |

0.15-0.25 |

0.02-0.06 |

0.01-0.03 |

0.03-0.06 |

0.2-0.7 |

0.02-0.4 |

| Foam structure |

closed cell |

closed cell |

closed cell |

closed cell |

closed cell |

cell |

| Flexibility |

✓Excellent |

fair |

fair |

fair |

fair |

fair |

| Re-bound |

✓Excellent |

good |

poor |

fair |

fair |

fair |

| Low temperature resistance |

✓Excellent |

good |

good |

fair |

good |

fair |

| Izod Impact |

good |

Excellent |

poor |

Excellent |

fair |

good |

| Chemical resistance |

✓Excellent |

Excellent |

poor |

good |

good |

fair |

| Mechanical properties |

✓Excellent |

Excellent |

poor |

good |

fair |

poor |

| Weatherability |

✓Excellent |

Excellent |

poor |

fair |

fair |

fair |

| Abrasion resistance |

✓Excellent |

good |

poor |

good |

poor |

fair |

| Environmental friendly |

✓Excellent |

Excellent |

poor |

Excellent |

fair |

poor |

| Rating |

✓5 |

5 |

3 |

4 |

2 |

2 |

ETPU Product

| Product Specifications | Product Feature | Bulk density(kg/m3) | Pellet size(mm) | Hardness (Asker C) |

|---|

| 6310BM |

Weight lighter. Made from ether type thermoplastic polyurethane (TPU) with excellent hydrolysis resistance, high compression resistance & elasticity(>60%). |

100~120 |

4~7 |

30~37 |

| 6315BM |

Made from ether type thermoplastic polyurethane (TPU) with excellent hydrolysis resistance, high compression resistance & elasticity(>60%). |

120~145 |

4~7 |

33~40 |

| 6315BS |

Particles smaller with finer texture. Made from ether type thermoplastic polyurethane (TPU). |

120~160 |

2~4 |

33~40 |

| 6315CM |

Made from ether type thermoplastic polyurethane (TPU) with excellent hydrolysis resistance, high compression resistance, good energy-absorption capability. |

120~145 |

4~7 |

40~47 |

| 6315DM |

Made from ether type thermoplastic polyurethane (TPU) with higher hardness of finished good. For airless tire application. |

130~170 |

4~7 |

60~65 |

* Note: These figures are for reference only. We're happy to customize products according to your specifications.

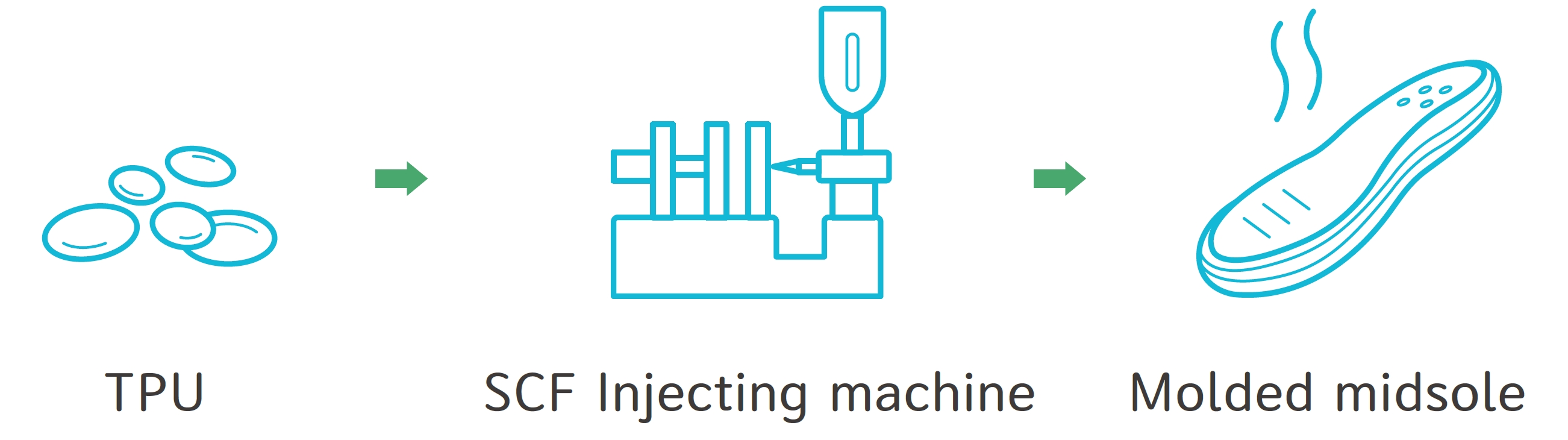

ETPU supercritical SCF physical foam

SCF supercritical fluid

Sustainable, Clean, Odorless

When the pressure and temperature of the gas above its critical point, the supercritical fluid characteristics will appear, which has properties between those of gas and liquid, and can be used as a good physical foaming agent.

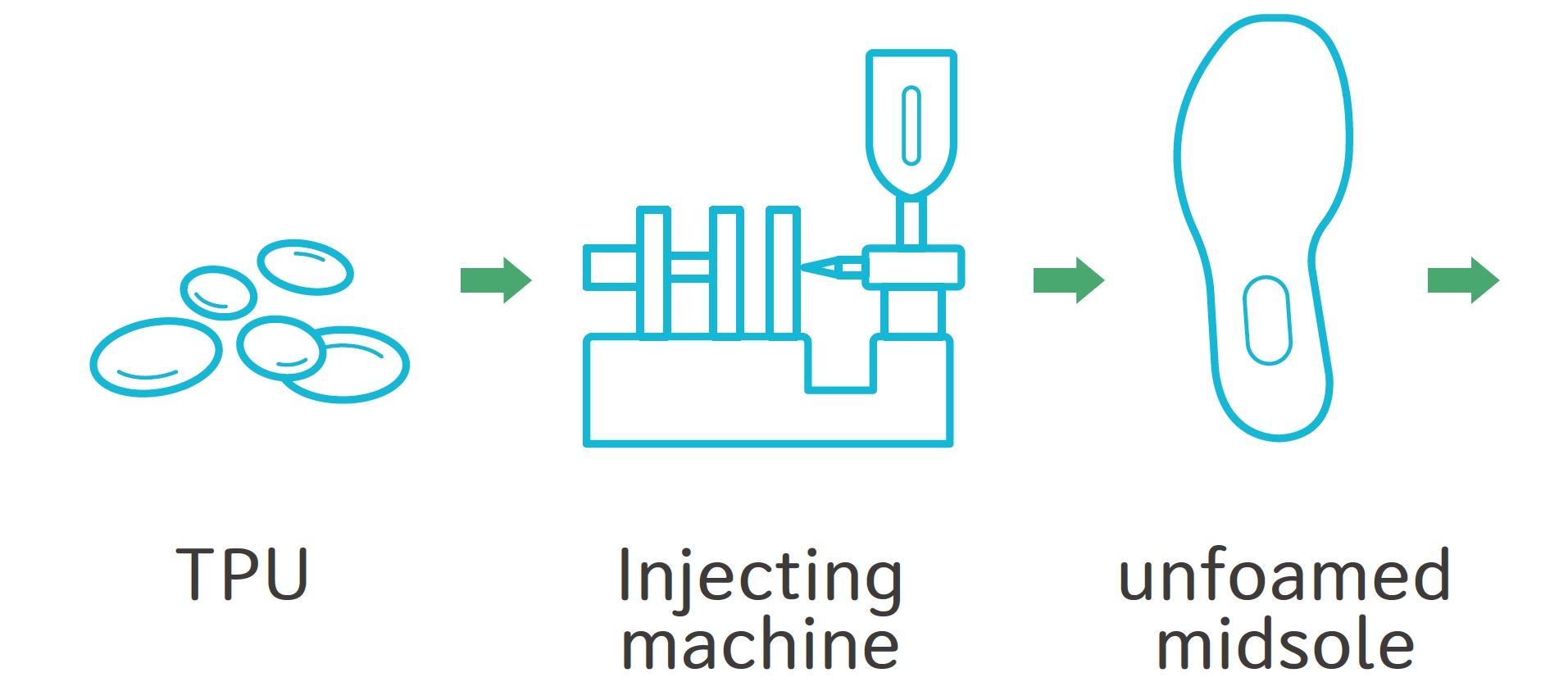

▪️Injection foaming

In injection machine, the SCF blowing agent is added and mixed with polymer, and then it is injected into the mold for foaming.

▪️Autoclave foaming

First shoot TPU is injectied to a unfoamed midsole, then put the unfoamed midsole into a high-pressure autoclave Relieve pressure and foam into a foamed midsole, and then put it into a hot and cold press machine to shape.

TPU products used in the foaming field

| Item | Injecting/ Autoclave foam Density (kg/m3) | Product feature |

|---|

| 1085AU-BF |

0.18~0.22 / 0.16~0.20 |

It has a good mechanical strength and a relatively high cost performance |

| 3085AU-BF |

0.15~0.20 / 0.12~0.17 |

It is made of polyether TPU, which has excellent hydrolysis resistance and good resilience (>60%) |

| 7385A-BF |

0.15~0.20 / 0.12~0.17 |

It is made of aliphatic polyether TPU, which has excellent hydrolysis resistance, good resilience (>60%) , and non-yellowing properties. |

| 3090AU-BFL |

0.19-0.24 / 0.16~0.21 |

It has excellent cushioning properties and can be used in energy-absorbing products such as protective gear and safety helmets. |

* Note: These figures are for reference only. We're happy to customize products according to your specifications.

Application

ISOTHANE ETPU - Colorful foam beads with high elasticity

Suitable for footwear materials, Buffer device for sports, Bicycle saddles , Running tracks, Airless tires.

.jpg)

.jpg)

.jpg)