Characteristics

Characteristics

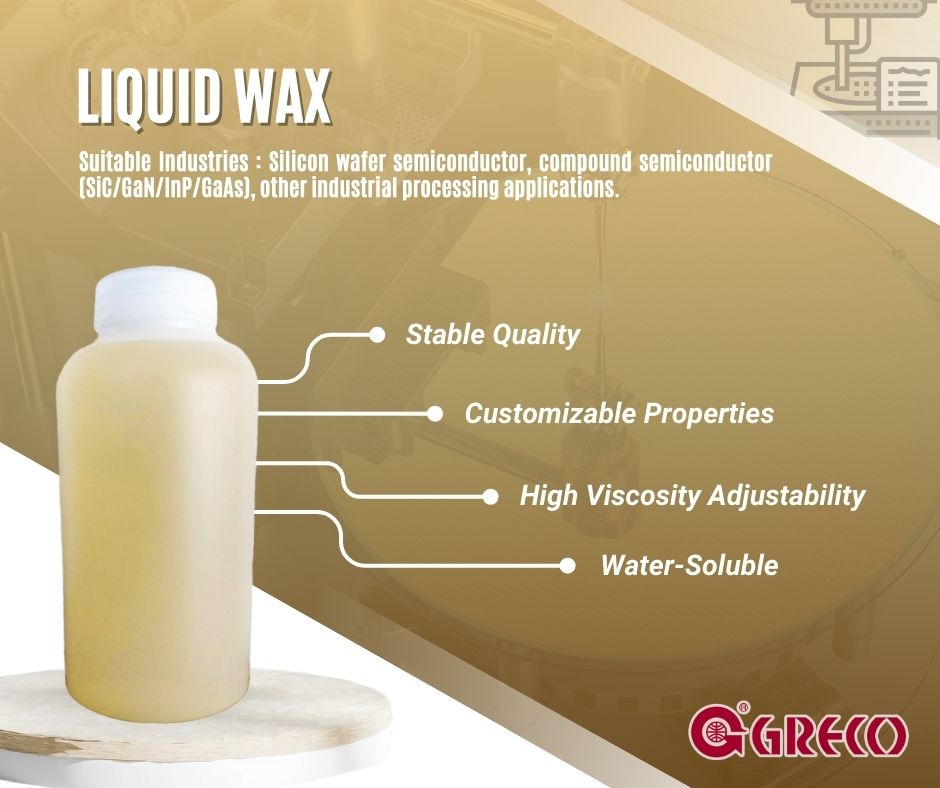

Liquid Wax provides temporary adhesion, enabling workpieces to bond to the process substrate, facilitating high-precision and high-strength operations such as polishing, grinding, and wafer thinning.

Application

- Suitable Industries :

Silicon wafer semiconductor, compound semiconductor (SiC/GaN/InP/GaAs), other industrial processing applications.

- Suitable Processes :

Grinding/Polishing/Thinning/Cutting etc.

- Equipment Requirements :

Recommended to use with a spin coater for waxing.

Features

- Stable Quality: Utilizes chemically synthesized resin as the main component, ensuring consistent material properties and resolving the quality variation issues associated with natural rosin due to seasonal, regional, and growth process differences.

- Customizable Properties: The molecular structure of the synthetic resin can be designed according to customer process conditions, providing suitable adhesive wax properties to meet process requirements.

- High Viscosity Adjustability: Allows for high variability in viscosity, achieving the desired film thickness by adjusting the composite formula and spin coater parameters.

- Water-Soluble: The synthetic resin product has good water solubility, allowing for easy cleaning with water without the need for additional solvents such as IPA.

Specification

| Item No. | Appearance | Solids content | Ph | Viscosity (R/T) | Softening point |

|---|

| GSW3 |

Light yellow liquid |

40% |

9~10 |

200 cp |

90~95℃ |